About us

Technology, quality, experience, sustainability and Just in Time delivery: these are the advantages of EuroMouldings. We are happy to tell you more about our strengths.

Technology

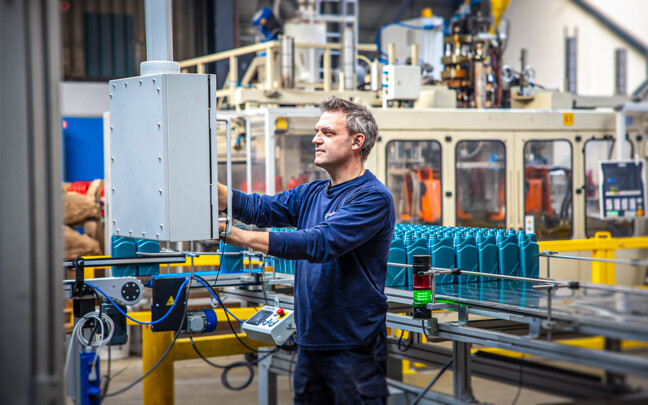

Already over 30 years' experience in producing packaging through the so-called extrusion blow moulding (EBM). Some technical spearheads:

- More than 45 extrusions blow moulding (EBM) machines that produce single, double or quadruple;

- For bottles, jerry cans and technical items;

- Possible to produce for a capacity of 250 ml up to and including 25 litres;

- A central piping system provides the machines with raw material in granulate form, possibly provided with colourant or other additive.

How Extrusion Blow Moulding (EBM) works:

- An extruder heats the granulate to create a liquid;

- The liquid mass is blown into the desired shape in a mould and cooled;

- After passing leakage tests, the packages are removed and packed automatically;

- We use modular moulds to optimise machine fleet use and maximise flexibility;

- The moulds can always be used on multiple machines to safeguard production continuity.

History of EuroMouldings

Ten Cate Mouldings

In 1977, the development department TtC Mouldings – short for Thiokol-ten Cate Mouldings – was established as a joint venture between the American company Thiokol and the Royal Nijverdal-Ten Cate Group. The company was based in Oldenzaal. TtC Mouldings was the first Ten Cate company to transition from full or partial textile production to a complete focus on plastics processing. In collaboration with Royal Shell Netherlands, research was carried out into how polypropylene, a by-product of the chemical industry, could be modified to make it suitable for extrusion blow moulding (EBM) of plastic jerry cans. The company was a true pioneer in this field: while others primarily used conventional plastics such as polyethylene and PVC, TtC Mouldings took an innovative approach by working with polypropylene. In 1990, the company was renamed Ten Cate Mouldings, focusing primarily on the production of jerry cans.

Polymij Kunststoffen B.V.

In 1977, Polymij Kunststoffen B.V. was established at what is now the current location of EuroMouldings. The company mastered a range of techniques – extrusion blow moulding (EBM), co-extrusion blow moulding, regranulation, screen printing, and therimage – placing it well ahead of its time in the market. Over the course of its seventeen-year existence, Polymij built a solid reputation in the reprocessing of polypropylene and polyethylene waste. What began as a practical solution for reusing internal 'waste' and by-products has since become a standard practice in sustainable plastics processing. Polymij specialised in the blow moulding of bottles ranging in volume from 100 ml to 5 litres, with a strong emphasis on the lubricants industry. Thanks to integrated techniques such as screen printing and therimage, the company was able to deliver fully finished products – ready for use straight from the production line.

Euro bv

Euro bv was founded in 1995 in Vroomshoop as a subsidiary of the Aufderhaar Kunststof Groep (AKG), now known as Veolia. The company specialised in the blow moulding of plastic packaging for both food and non-food applications, with volumes ranging from 100 ml to 5 litres. Euro bv actively responded to the growing demand for innovative products in which extrusion blow moulding (EBM) played a central role. Bespoke solutions were more the rule than the exception. The development process began – and still begins – with the design, which was carried out entirely in-house. The ability to think alongside customers, combined with extensive knowledge of the entire design and production process, was Euro bv’s key strength. Over the years, this added value has only continued to grow.

Euro Mouldings bv

In 1997, Euro bv acquired the company Polymij and relocated its production activities from Vroomshoop to the Polymij site. This move resulted in a doubling of the machine fleet and created room for further organisational growth. In 1999, Euro B.V. became an independent company. Midway through that same year, it acquired Ten Cate Mouldings, which was subsequently integrated into the Nijverdal site. This marked the official establishment of Euro Mouldings bv. The combined expertise in extrusion blow moulding (EBM) and experience from various market segments and product lines came together within Euro Mouldings. For the first time, the company was able to offer its customers a complete packaging portfolio – with solutions ranging from 100 ml to an impressive 30 litres.

Euro Mouldings

In 1999, the logos of Euro bv and Ten Cate Mouldings were merged to create a stronger, unified identity for the market. Over the following years, Euro Mouldings established itself as a recognised name in the industry as a complete solutions provider. The company was increasingly seen not merely as a extrusion blow moulder (EBM) of bottles and jerry cans, but as a partner offering comprehensive packaging solutions. By 2007, it was time to visually reflect this evolution — the logo was refreshed to better represent the company’s broader profile.

EuroMouldings part of AST

In 2018, under the leadership of AST, a deliberate decision was made to take the next step in the company’s ambition: to become one of Europe’s leading producers of blow-moulded plastic packaging. AST is the market leader in the production of plastic jerry cans and drums with UN certification, and as a family-owned business, it boasts over 40 years of experience in plastic blow moulding. From its headquarters in Erndtebrück, several new branches have been established across Europe in recent years. The technical expertise and strong reputation that EuroMouldings has built up over the years were decisive factors for AST in making this strategic choice. The joint goal is clear: to fully and comprehensively support customers with a broad product portfolio ranging from 250 ml up to an impressive 220 litres. While AST primarily focuses on jerry cans and drums, EuroMouldings brings valuable added breadth through its extensive range of bottles.

Our customers are looking for a packaging supplier who can keep pace with the unpredictable movements of the market. We are that supplier – a true partner to our customers. Our key strengths: quality, speed of delivery, close collaboration, and a constant drive for improvement. As a specialist in extrusion blow moulding (EBM) of plastic packaging – from bottles to jerrycans and technical components – we combine craftsmanship with flexibility. Our team members can rely on one another and are always ready to lend a hand.

Sustainability

We are conscious of the positive contribution we can make to our environment by making our production process and the products we deliver more sustainable. We employ a variety of methods aimed at achieving this. Our sustainability policy therefore includes, among other things, energy savings, reconditioning and cradle-to-cradle production.

Just in Time delivery

You want to manage your warehouse space as efficiently as possible. We can therefore keep your products in stock and deliver them when you need them. You can opt for production and delivery to order, but also for daily Just in Time deliveries, using swap trailers. We will consult with you to discuss forecasts to ensure optimal production planning.

High quality

Speed and accuracy are essential for your highly automated filling processes. We help you to prevent product errors and to pursue ‘zero defects’. We are working hard to guarantee the high quality we offer you in the future. That is why we continuously invest in online measurement systems and training courses. EuroMouldings is certified as a training company by PLMF for the training of operators according to the VAPRO method.

Working at

EuroMouldings

Current number of vacancies 6